PRODUCTS

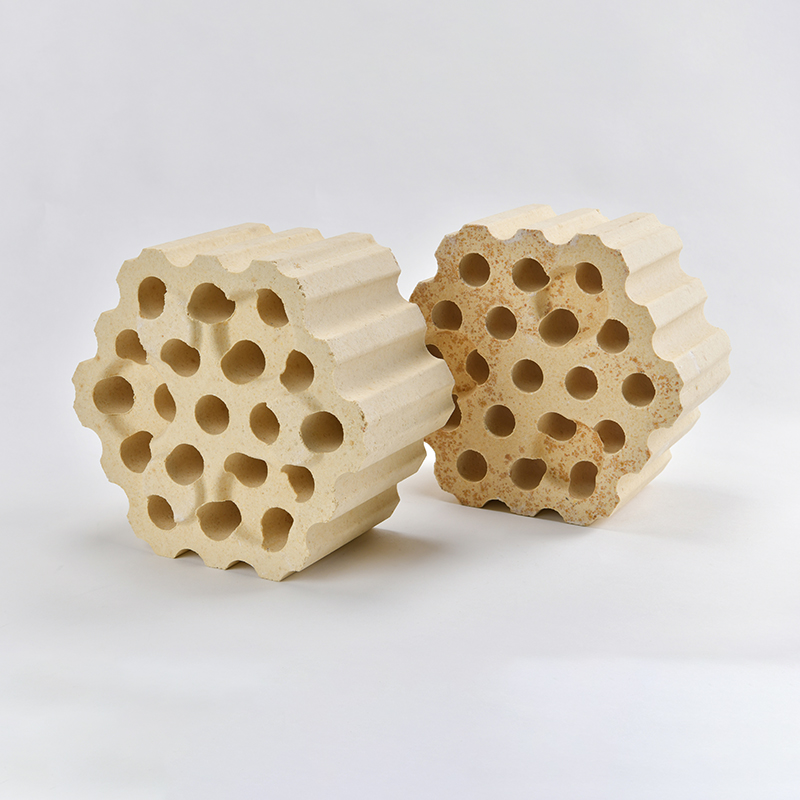

Silicon Checker Brick 19 Holes

Description

Silica lattice bricks are used as carriers of high-temperature heat. Its working principle is to first burn coal gas, use the high-temperature flue gas generated to heat the checker bricks in the regenerator, and then heat the cold air through the hot checker bricks, causing the hot air stove to rotate alternately. Carry out combustion and air supply, and continuously obtain high-temperature hot air in the blast furnace. The function of the hot blast furnace is to heat the cold air sent into the blast furnace by the blower into hot air, and then send the hot air into the blast furnace through the hot air duct for combustion reaction.

During the air supply period, the cold air blown by the blower enters the hot air furnace, is heated by the checker bricks into hot air, and is sent to the blast furnace through the hot air duct. Checkered bricks are mainly used in hot blast stoves. When the hot air temperature is lower than 900℃, clay is generally used. When the air temperature is higher than 900°C, the material of the checker bricks is high alumina, mullite, sillimanite, and silicon.

Silica bricks parameter

| ITEM | YC-94K | YC-95B | YC-95A | YC-96B | YC-96A | |

|---|---|---|---|---|---|---|

| SiO2 % | ≥94 | ≥95 | ≥95 | ≥96 | ≥96 | |

| Fe203 % | ≤1.5 | ≤1.2 | ≤1.2 | ≤1.0 | ≤0.8 | |

| Refractoriness ℃ | ≥1710 | ≥1710 | ≥1710 | ≥1710 | ≥1710 | |

| A.P % | ≤24 | ≤22(24 | ≤22(24) | ≤22(24) | ≤22(24) | |

| B.D g/cm3 | ≤2.33 | ≤2.35 | ≤2.35 | ≤2.34 | ≤2.34 | |

| MPa | ≥20KG | ≥30 | ≥30(25) | ≥30(25) | ≥30(25) | ≥30(25) |

| <20kg | ≥35(30 | ≥35(30) | ≥35(30 | ≥35(30) | ||

| RUL ℃ | ≥1630 | ≥1650 | ≥1660 | ≥1670 | ≥1680 | |

Silicon lattice brick application

Silicon check bricks are mainly used in hot blast stoves. When the hot air temperature is lower than 900℃, clay is generally used. When the wind temperature is higher than 900℃, the silicon grid bricks are made of high alumina, mullite, sillimanite and silicon.

Under the same conditions, large blast furnaces use traditional 7-hole bricks with a diameter of 30mm and 19-hole bricks with a diameter of 43mm, which increase the air temperature by 38°C; small and medium-sized blast furnaces use 19-hole bricks with a diameter of 25mm and 31-hole bricks, which increase the air temperature by 19°C.