PRODUCTS

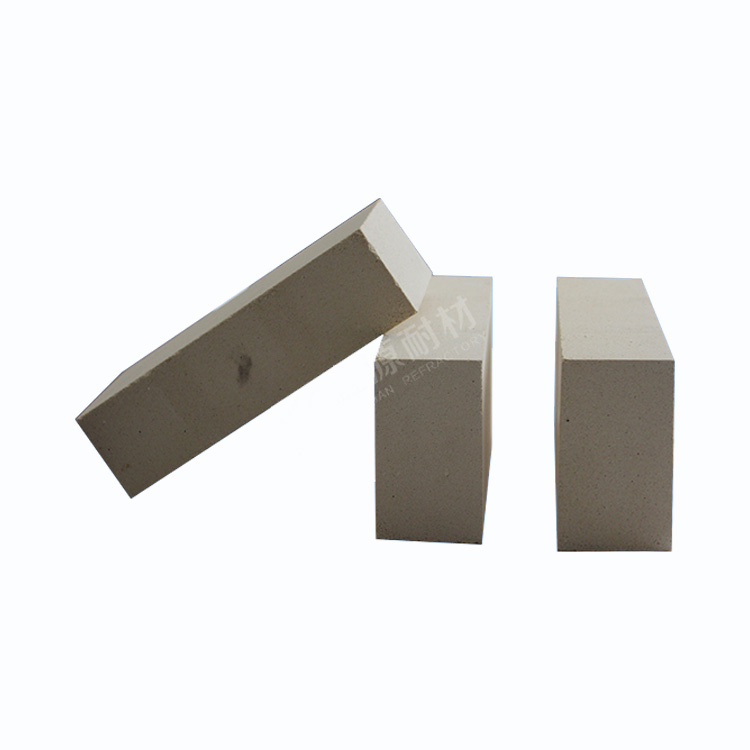

Lightweight Mullite Bricks 1.0

Description of Lightweight Mullite Brick

High-alumina refractory materials with mullite as the main crystal phase generally have an alumina content of 50%-75%. The refractory temperature of mullite lightweight bricks can reach above 1790℃. The load softening starting temperature is 1600-1700℃. The room temperature pressure resistance is light 70-260MPa. Good thermal shock resistance. There are two types: sintered mullite bricks and fused mullite bricks.

Sintered mullite bricks are made of high-alumina bauxite clinker as the main raw material, with a small amount of clay or raw bauxite as a binder, and are formed and sintered. Fused mullite bricks are made of high-alumina bauxite, industrial alumina and refractory clay, with charcoal or coke fine particles added as a reducing agent. After forming, they are manufactured by reduction fusion method. The crystals of fused mullite are larger than those of sintered mullite, and the thermal shock resistance is better than that of sintered products. Their high-temperature performance mainly depends on the content of alumina and the uniformity of the distribution of mullite phase and glass.

A high-alumina refractory material with mullite (3Al2O3·2SiO2) as the main crystal phase. The general alumina content is between 65% and 75%. In addition to mullite, the mineral composition also contains a small amount of glass phase and quartz with a lower alumina content; and a small amount of corundum with a higher alumina content. Lightweight mullite bricks can be directly used for high-temperature kiln linings, and are currently widely used in shuttle kilns, roller kilns, glass and petrochemical kiln linings.

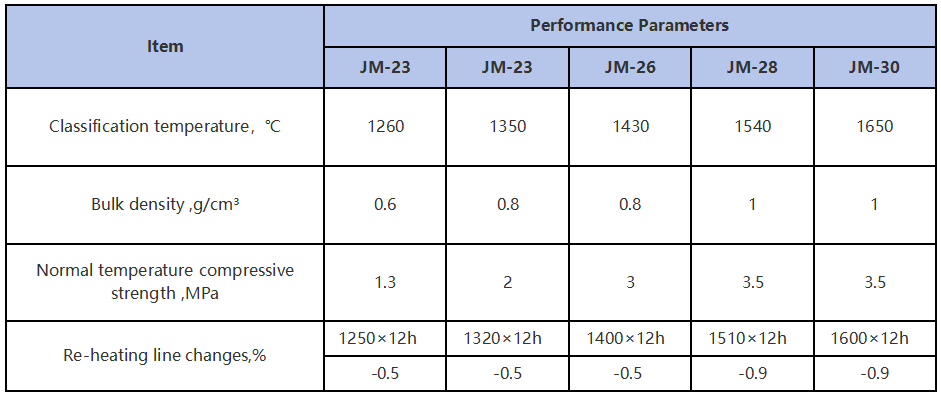

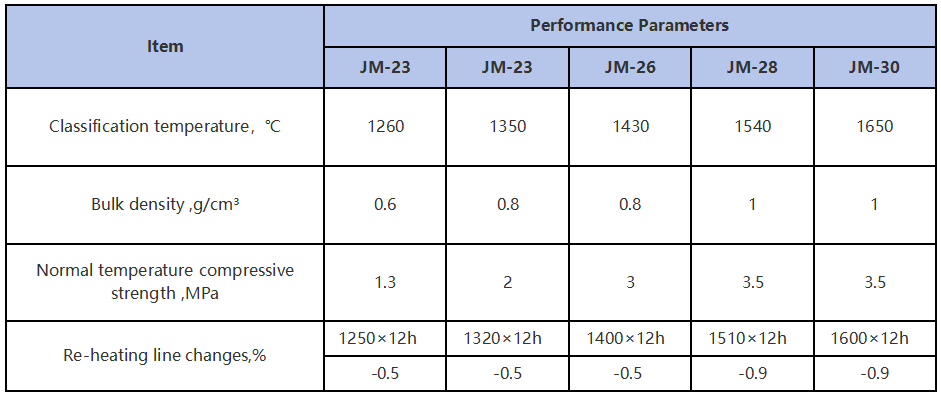

The physical and chemical parameters of lightweight mullite bricks are as follows:

Applied to:

Glass melting furnace upper structure material channel bricks, modification plates, processing kiln upper structure, E-glass melting furnace bricks. Firing kilns, smelting kilns, refining devices, heating devices, and other thermal equipment. Application areas: ceramic industry, glass industry, steel industry, petrochemical industry, aluminum industry, and other industrial fields.