PRODUCTS

Ceramic Fiber Board

Description of Ceramic Fiber Fiber

Ceramic Fiber is a new type of lightweight and energy-saving refractory material. It is made of coke as the main raw material, melted at a high temperature of 2100℃, and processed by high-speed centrifugal method or blowing method to produce cotton-like inorganic fiber. Its main chemical components are SiO2 (48~52%), Al2O3 (43~49%), Fe2O3 (0.9~0.13%), CaO (less than 1%), and MgO (trace).

Ceramic Fiber has the advantages of high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity, good resistance to mechanical vibration, small thermal expansion, and good thermal insulation performance. It can be made into Ceramic Fiber board, Ceramic Fiber felt, Ceramic Fiber rope, Ceramic Fiber blanket and other products through weaving or weaving. It is a new material to replace asbestos and is widely used in thermal insulation of thermal energy equipment in metallurgy, electricity, machinery, and chemical industry.

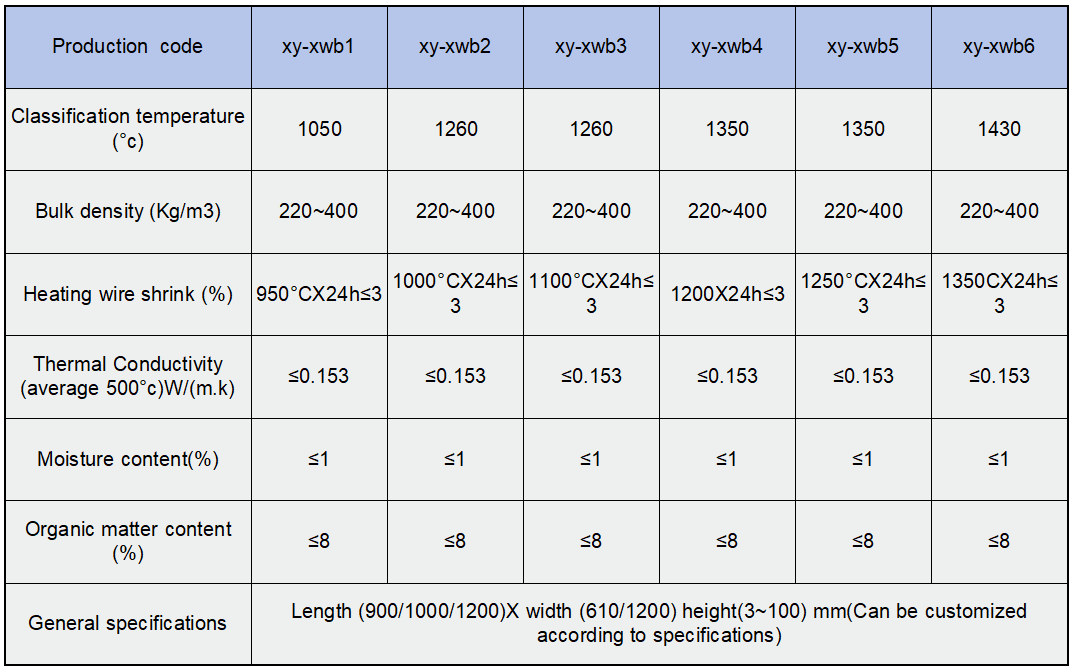

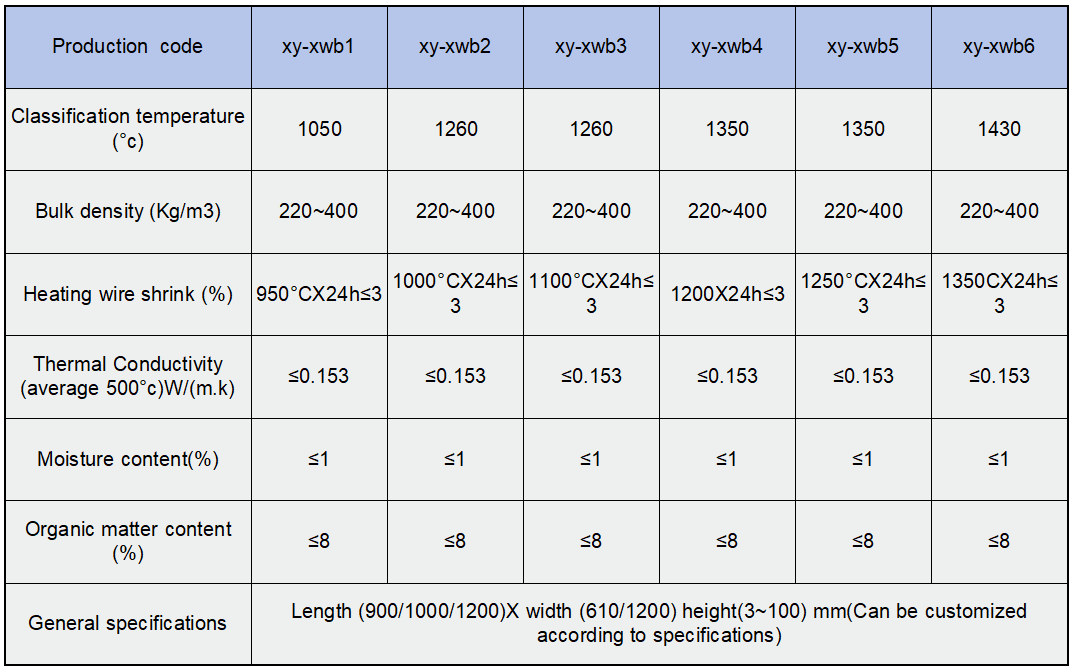

Parameter of Ceramic Fiber Board

Product Features

● Low heat capacity, low thermal conductivity

● High compressive strength Non-brittle, good toughness Continuous production, easy processing and installation

● Accurate size, good flatness

● Excellent thermal stability and thermal shock resistance