PRODUCTS

High Alumina Checker Brick (Checker Brick-19 holes)

Description of High Alumina Checker Brick

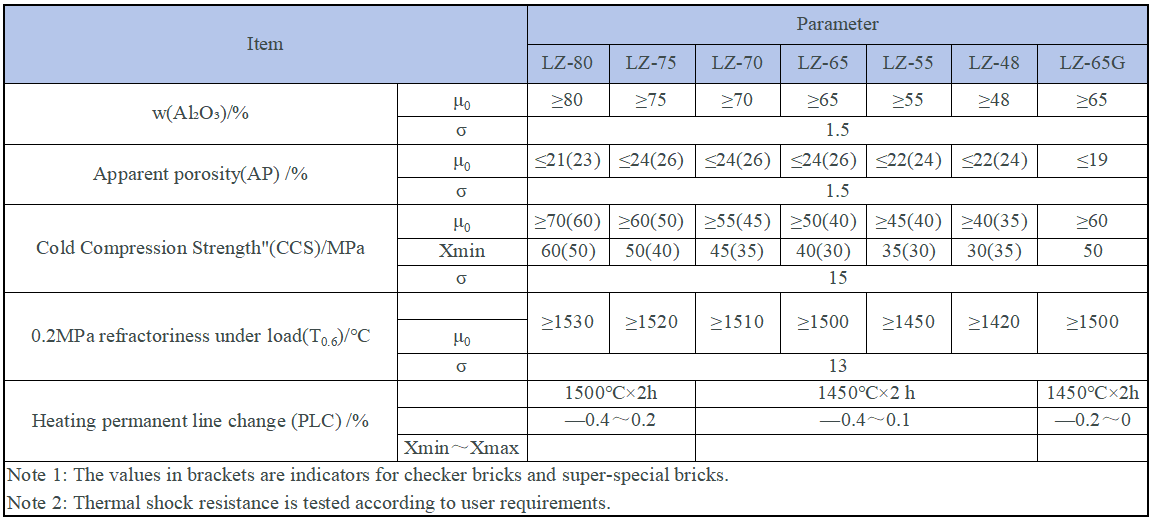

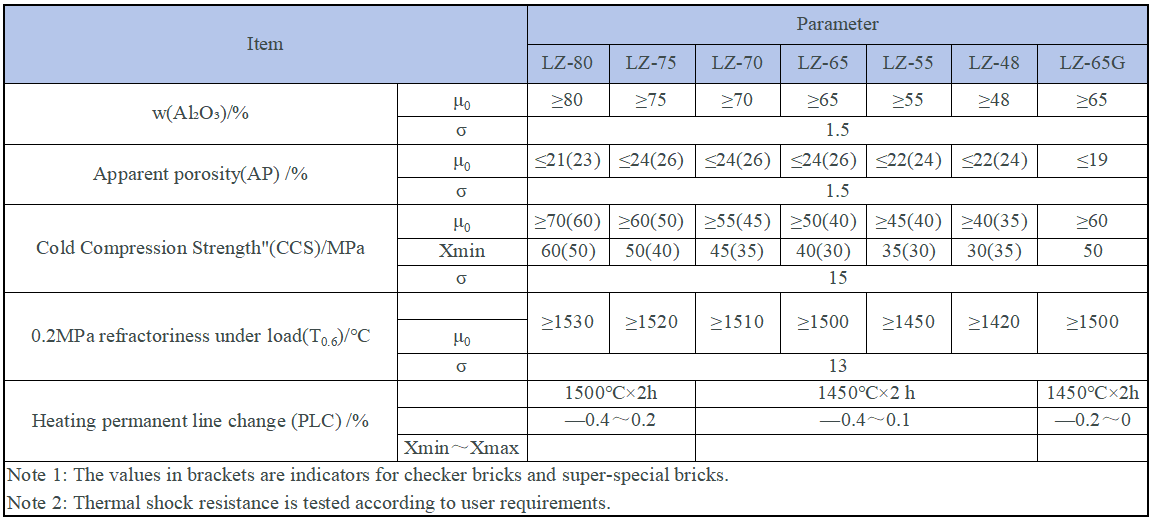

If the Al2O3 content is higher than 90%, it is called corundum brick. Due to different resources, the standards of various countries are not completely consistent. For example, European countries stipulate that the lower limit of Al2O3 content for high-alumina refractories is 42%. In China, high alumina bricks usually refer to refractory bricks with an Al2O3 content of more than 48%. They are mainly made of natural high-grade bauxite, which contains minerals such as diaspore, bomerite, kaolinite, etc. Soft or semi-soft clay is added to the high-alumina clinker as a binder to start batching and mixing, and then it is formed, dried, and finally fired. The refractoriness of high alumina bricks is about 1770℃, and the load softening temperature is 1420℃-1550℃. Common high alumina bricks are LZ-80, LZ-75, LZ-65, LZ-55, LZ-48, etc. It is mainly used for lining blast furnace, hot blast furnace, ore-heat furnace, electric furnace roof, blast furnace, reverberatory furnace and rotary kiln. In addition, high alumina bricks are also widely used as open-hearth heat storage checker bricks, plugs for pouring systems, nozzle bricks, etc.

High Alumina Brick Parameters

Remark:

This data sheet is just for your reference.

If you have special requirements, please contact with us.

Application Of High Alumina Checker Brick

High Alumina Checker Brick are mainly used in blast furnace hot blast furnaces and flame furnaces.

High Alumina Checker Brick are mainly used in the regenerator of hot blast stoves. High Alumina Checker Brick with a certain structure and grid holes are arranged in an orderly manner. The upper and lower through holes of the checker bricks can allow gas to pass through. According to the technical requirements of different temperature zones, siliceous check bricks, clay bricks, etc. are generally used. In some hot blast stoves, high alumina bricks, mullite bricks, sillimanite bricks, etc. are also selected.

The function of the hot blast stove is to heat the cold air sent by the blower to the blast furnace into hot air, and then send the hot air to the blast furnace through the hot blast duct for combustion reaction. The blast furnace hot blast stove has a furnace burning period and an air supply period, and the two working periods rotate periodically. During the burning period, the burned high-temperature flue gas passes through the holes of the checker bricks of the hot blast furnace and transfers heat to the checker bricks; during the air supply period, the cold air from the blower enters the hot blast furnace and is heated by the checker bricks into hot air. Sent to the blast furnace through hot air duct.