Xinyuan Refractory

The Jiayuguan project of Sunstone Development is a high-end negative electrode material production project, which aims to improve the production capacity and technical level of negative electrode materials. The project has newly built 20 graphitization furnaces. Our company provided a full set of refractory materials for the project, including high-alumina bricks, clay bricks and refractory mud. With our support, the project successfully improved the service life and stability of the graphitization furnace, ensuring the efficiency and safety of the production process.

In the 2*54 chamber project of Longxi aluminum carbon roasting furnace developed by Sunstone Development, our company provided low creep clay bricks, fire wall clay bricks and cross wall clay bricks. These refractory materials have excellent high temperature performance, low creep and thermal shock resistance, meeting the strict requirements of the roasting furnace in high temperature environment. Through our products, the production efficiency and the service life of the kiln have been significantly improved.

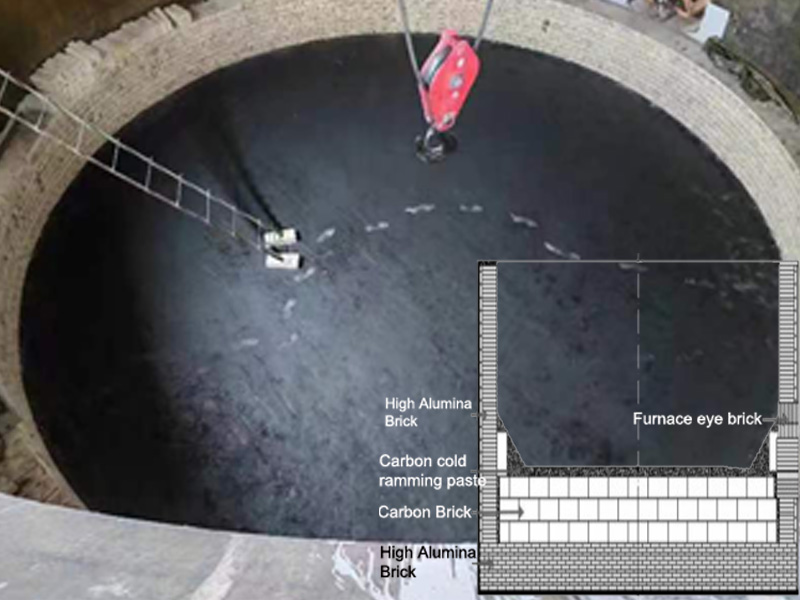

Yunnan Qujing Iron and Steel Group is an important steel production enterprise in the southwest of China. In the new No. 2 blast furnace project of Yunnan Qujing Iron and Steel Group's transformation and upgrading, our company successfully undertook the supply and construction of refractory materials for the hot blast furnace body refractory bricks, burner combination bricks, heat storage chamber lattice bricks and hot air ducts. The project was officially launched in June 2021 and successfully completed in June 2022.

Hoshine Silicon is an internationally renowned industrial silicon manufacturer. Our company supplies high-alumina bricks, microporous carbon bricks, silicon carbide furnace bricks and flue insulation spray coatings for the 32*33000KVA industrial silicon mining furnace project of Eastern Hoshine Silicon. We use a new type of furnace lining to greatly increase the service life of the kiln, and the matching silicon water bag uses silicon nitride combined with silicon carbide bricks to improve the refining efficiency and durability of the silicon bag.

In the 2*36-chamber graphite electrode baking furnace project of Haitai New Energy in Inner Mongolia, our company supplied all refractory products, including special clay bricks, fire channel wall clay bricks, furnace surface prefabricated blocks and castables and other refractory materials. The products ensure the efficient operation and long-term stability of the baking furnace, and improve the overall thermal performance and service life of the kiln and the overall thermal performance and service life of the equipment.

In the Panhua Steel Project in the Philippines, our company provided a full set of hot blast furnace refractory materials, including hot blast furnace body and burner refractory materials. We not only supplied high-quality refractory bricks and castables, but also provided professional design and construction services. Through careful design, we ensured the reasonable layout and optimal performance of the refractory materials, ensuring the efficient operation and long life of the hot blast furnace.

In the Zambia silicon kiln project, which was invested and constructed by Huaxin Cement, our company provided the lime kiln with wear-resistant high-alumina bricks, lightweight insulation bricks and lightweight castables. The product significantly extends the service life of the equipment, reduces energy consumption, and improves the energy efficiency of the kiln. At the same time, it achieves low investment and quick results for customers.

For Trina Solar's 4*33000KVA industrial silicon project, our company supplied flue insulation bricks and high-strength ceramic wear-resistant spray coatings, and adopted new furnace lining materials and advanced construction methods. Our products and technologies have improved the performance of the kiln, reduced energy consumption, and can be used for more than 5 years, reducing production costs for customers and improving their competitive advantages.