IIMVELISO

IAlumina Magnesia yeCarbon Brick

Inkcazo eneenkcukacha

Izinto ezichasayo ezisetyenziswe kumgca we-slag we-ladle yokuqala zidibene ngokuthe ngqo kunye nezitena ze-magnesia-chrome, ukunyibilika kombane kwaye emva koko zidibaniswe nezitena ze-magnesia-chrome kunye nezinye izitena eziphezulu ze-alkaline. Emva kokuba izitena ze-MgO-C zisetyenziswe ngempumelelo kubaguquli, izitena ze-MgO-C nazo zisetyenziswe kumgca we-slag we-ladle yokucoca, kwaye iziphumo ezilungileyo zifunyenwe. ilizwe lam kunye neJapan ngokubanzi zisebenzisa izitena ze-resin-bonded MgO-C kunye nomxholo wekhabhoni we-12% ukuya kwi-20%, ngelixa iYurophu isebenzisa kakhulu izitena ze-asphalt-bonded MgO-C, kunye nomxholo wekhabhoni malunga ne-10%.

I-Kokura Steel Works ye-Sumitomo Metal Corporation eJapan isebenzise izitena ze-MgO-C kunye nomxholo we-MgO we-83% kunye ne-C umxholo we-14-17% ukubuyisela ngokuthe ngqo izitena ze-magnesia-chrome kumgca we-slag we-VAD, kunye nobomi benkonzo ye-slag. umgca unyuswe ukusuka kumaxesha angama-20 ukuya kuma-30-32 amaxesha [9]. I-LF yokucoca i-ladle ye-Sendai Steel Plant eJapan isebenzisa izitena ze-MgO-C zokutshintsha izitena ze-magnesia-chrome, kwaye ubomi benkonzo yomgca we-slag bonyuswe ukusuka kumaxesha angama-20-25 ukuya kumaxesha angama-40, ukufumana iziphumo ezilungileyo. I-Osaka Ceramics Refractory Co., Ltd. yafunda imiphumo yekhabhoni kunye nohlobo lwe-antioxidant kwi-resistance oxidation, ukumelana ne-slag kunye nokushisa okuphezulu kwamandla okuguquguquka kwezitena ze-MgO-C. Uphononongo lubonisa ukuba izitena ze-MgO-C ezenziwe ngomxube we-magnesia edibeneyo kunye ne-sintered magnesia, kunye ne-15% ye-phosphorus graphite kunye nenani elincinci le-magnesium-aluminium alloy njenge-antioxidants, inomsebenzi omhle wokusebenzisa. Xa isetyenziswe kwi-100-ton LF ladle slag line, izinga lomonakalo liyancipha nge-20-30% xa kuthelekiswa nezitena ze-MgO-C kunye nekhabhoni ye-18% kunye ne-antioxidant, kunye ne-avareji yokuguguleka kwe-1.2-1.3 mm / eziko [1].

Ekubeni ilizwe lam izitena zomgca we-ladle slag zamkele izitena ze-MgO-C endaweni yezitena ze-magnesia-chrome, umphumo wokusetyenziswa ngokubanzi ucacile. I-Baosteel Group Corporation's 300t ladle slag line yaqala ukusebenzisa izitena ze-MT-14A magnesia-carbon ngoJulayi 1989, kwaye ubomi bomgca we-slag buhleli ngaphezu kwamaxesha angama-100; i-150T yombane we-ladle slag line isebenzisa izitena ze-carbon magnesia-carbon ephantsi ukunyibilikisa intsimbi yentambo, kunye nobushushu bokucofa kwe-1600 ℃ ~ 1670 ℃, ephumelele iziphumo ezicacileyo.

Inkampani yethu igxile ekuveliseni izitena zekhabhoni zemagnetia, izitena ze-aluminium-magnesia zekhabhoni, izitena ezingezizo zekhabhoni zokucoca iileyile, izitena ze-aluminiyam-silicon carbide zekhabhoni yeetanki ze-torpedo, kunye nezitena ezitsha ze-carbon-free magnesia kunye neerefractories ezahlukeneyo ze-amorphous, ezifana nokulungiswa. kunye nezixhobo zokudubula zokuguqula, iziko lombane kunye neeleyile. Sikwabonelela ngeemveliso ezenziwe nge-vibration, ezifana nezitena zomoya we-ladle, izitena zesihlalo somlomo we-nozzle ezinokungena emoyeni, izitena zesihlalo somlomo kunye nezinto ezenziwe kwangaphambili. Siye saphuhla saba lishishini elibanzi eliphikisayo elidibanisa uphando lwemathiriyeli ekrwada, ukusetyenzwa okunzulu kunye norhwebo. Ilabhoratri yethu inesethi epheleleyo yovavanyo kunye nezixhobo zokuhlola. Izixhobo zethu zinokwenza imathiriyeli ekrwada, iimveliso ezigqityiweyo, uvavanyo kunye nokuhlola, kunye nokuphuhlisa iimveliso ezintsha. Sikholelwa ukuba inzululwazi kunye neteknoloji sisikhokelo sethu. Ke ngoko, sifumene itekhnoloji ephezulu ekhaya nakwamanye amazwe, siphucula ngokuqhubekayo umgangatho wemveliso, umxholo wesayensi kunye nobuchwepheshe kunye nozinzo lwendalo, ngaloo ndlela siphucula itekhnoloji yemveliso kunye nokuhlaziya rhoqo izixhobo zethu zemveliso. Sinikezela ngoluhlu olupheleleyo lweenkonzo zobuchwepheshe ngokobukhulu kunye neeparitha zobugcisa zabaguquli, ii-arc zombane zombane kunye neeleyile ngokweemfuno zabathengi.

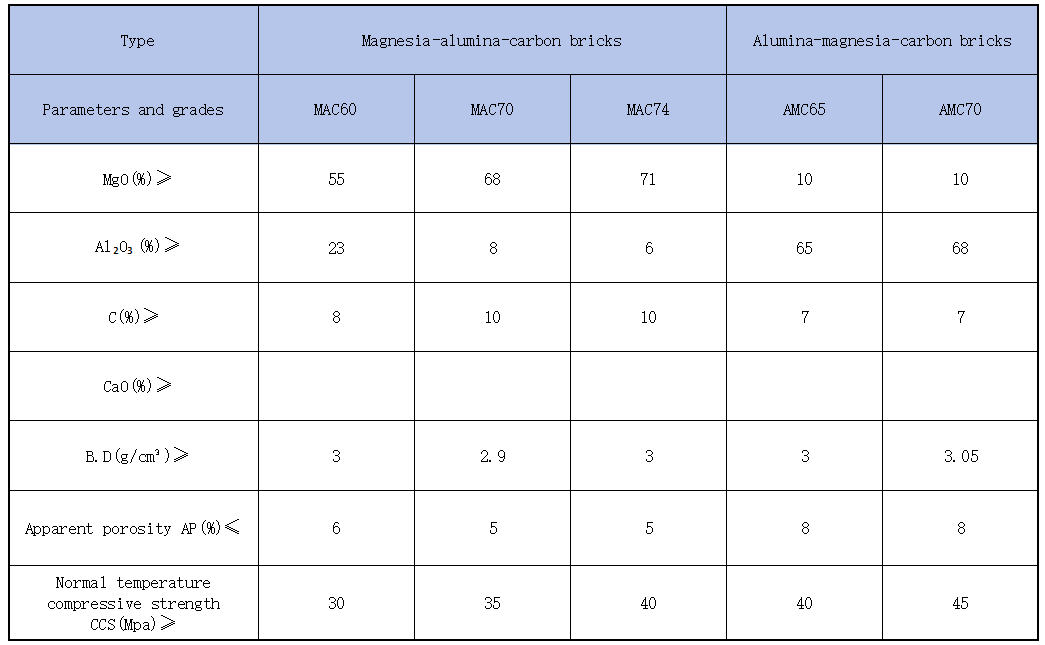

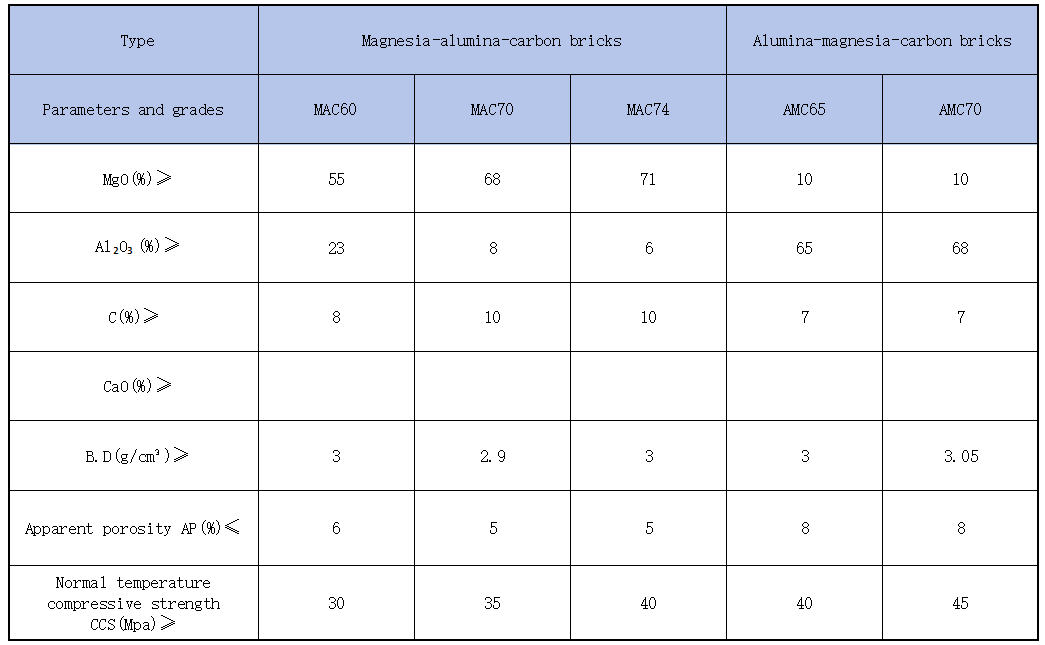

Iiparamitha zezitena ze-Magnesium carbon

Iiparamitha zezitena ze-Magnesium carbon