Ngwaahịa

Carbon calcining ọkụ silica brik

Nkọwa zuru ezu

A na-ejikọta ihe ndị na-emegharị ihe na-eji na slag line nke mbụ ladle na brik magnesia-chrome, ọkụ eletrik wee jikọta ya na brik magnesia-chrome na brik alkaline ndị ọzọ dị elu. Mgbe ejiri brik MgO-C mee ihe nke ọma na ndị na-agbanwe agbanwe, a na-ejikwa brik MgO-C mee ihe n'ahịrị slag nke ladle nnụcha, ma rụpụta ihe dị mma. Obodo m na Japan na-ejikarị brik MgO-C resin nwere ọdịnaya carbon nke 12% ruo 20%, ebe Europe na-ejikarị brik MgO-C nwere asphalt, yana ọdịnaya carbon nke ihe dịka 10%.

Ọrụ Kokura Steel nke Sumitomo Metal Corporation dị na Japan jiri brik MgO-C nwere ọdịnaya MgO nke 83% yana ọdịnaya C nke 14-17% dochie brik magnesia-chrome jikọtara ọnụ na ahịrị VAD slag, yana ndụ ọrụ slag. abawanyela ahịrị site na ugboro 20 ruo ugboro 30-32 [9]. Igwe nchacha LF nke Sendai Steel Plant na Japan jiri brik MgO-C dochie brik magnesia-chrome, na ndụ ọrụ nke eriri slag mụbara site na oge 20-25 ruo ugboro 40, na-enweta nsonaazụ dị mma. Osaka Ceramics Refractory Co., Ltd. mụrụ mmetụta nke ọdịnaya carbon na ụdị antioxidant na nguzogide oxidation, nguzogide slag na ike mgbanwe okpomọkụ nke brik MgO-C. Ọmụmụ ihe ahụ na-egosi na brik MgO-C mere nke ngwakọta nke magnesia fused na sintered magnesia, na 15% phosphorus graphite na obere ego nke magnesium-aluminom alloy dị ka antioxidants, nwere mmetụta dị mma. Mgbe ejiri ya na 100-ton LF ladle slag line, ọnụ ọgụgụ mmebi ahụ na-ebelata site na 20-30% ma e jiri ya tụnyere brik MgO-C nwere ọdịnaya carbon nke 18% na enweghị antioxidant, na nkezi nke mbuze bụ 1.2-1.3 mm/ ọkụ [1].

Ebe ọ bụ na brik ahịrị ladle slag a nụchara anụcha nke obodo m nakweere brik MgO-C kama brik magnesia-chrome, mmetụta ojiji zuru oke apụtawo. Baosteel Group Corporation's 300t ladle slag line malitere iji brik MT-14A magnesia-carbon na Julaị 1989, na ndụ ahịrị slag nọgidere n'elu 100 ugboro; na 150T electric oven ladle slag line na-eji obere carbon magnesia-carbon brik na-agbaze ụdọ ígwè, na a tapping okpomọkụ nke 1600 ℃ ~ 1670 ℃, nke enwetawo doro anya pụta.

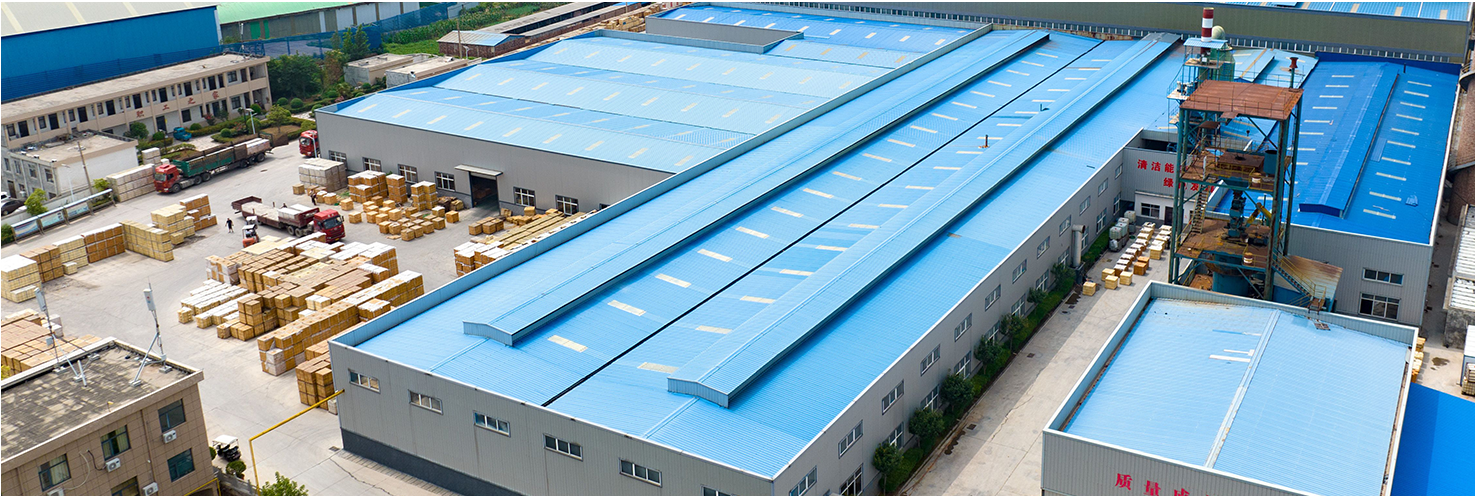

Ụlọ ọrụ anyị pụrụ iche na mmepụta nke brik carbon magnesia, aluminom-magnesia carbon brik, brik na-abụghị carbon maka ladles a nụchara anụcha, aluminom-silicon carbide carbon brik maka tankị torpedo, na brik magnesia na-enweghị carbon na ihe dị iche iche amorphous refractories, dị ka nrụzi. na ngwa egbe maka ntụgharị, ọkụ ọkụ na ladles. Anyị na-enyekwa ngwaahịa ndị emebere ịma jijiji, dị ka brik ikuku ladle, brik oche nozulu ikuku na-eme ka ikuku, brik oche oche nozzle na ihe ndị etinyegoro. Anyị na-etolite n'ime a keukwu refractory Enterprise integrating raw material research, miri nhazi na ahia. Ụlọ nyocha anyị nwere ngwa nyocha na nyocha zuru oke. Akụrụngwa anyị nwere ike imepụta akụrụngwa, ngwaahịa emechara, nwalee na nyocha, wee mepụta ngwaahịa ọhụrụ. Anyị kwenyere na sayensị na teknụzụ bụ nduzi anyị. Ya mere, anyị enwetala nkà na ụzụ dị elu n'ụlọ na ná mba ọzọ, na-aga n'ihu na-eme ka ngwaahịa ngwaahịa dịkwuo mma, ọdịnaya sayensị na nkà na ụzụ na nkwụsi ike dị n'ime ya, si otú ahụ na-eme ka nkà na ụzụ mmepụta ihe dịkwuo mma ma na-emelite ngwá ọrụ mmepụta anyị mgbe niile. Anyị na-enye ọrụ ọrụ nka zuru oke dịka nha na oke teknụzụ nke ndị ntụgharị, ọkụ ọkụ eletrik na ladles dị ka ihe ndị ahịa chọrọ.

Silica brik parameters

Silica brik parameters